About us

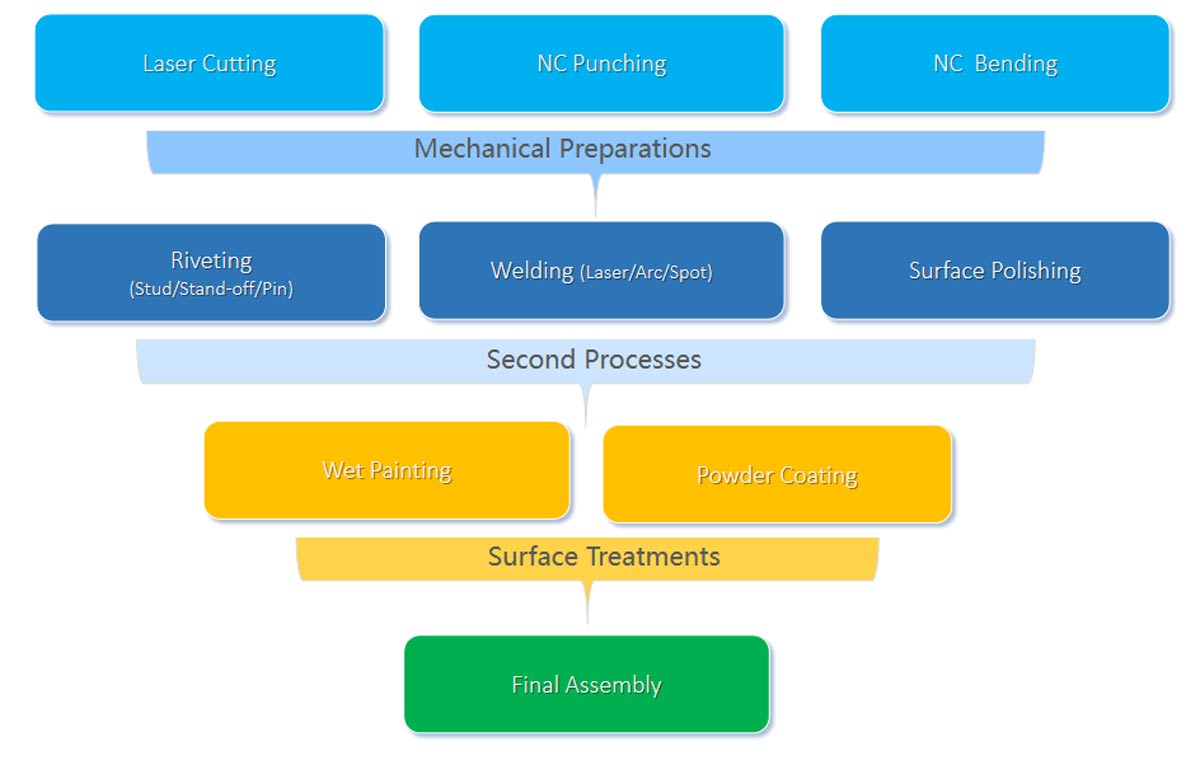

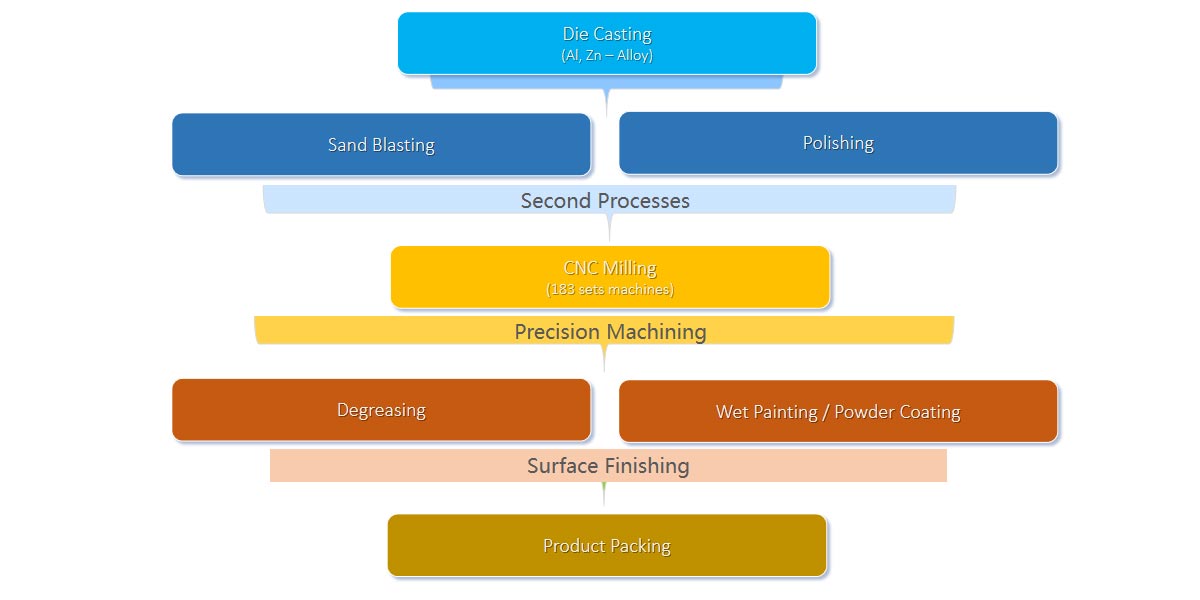

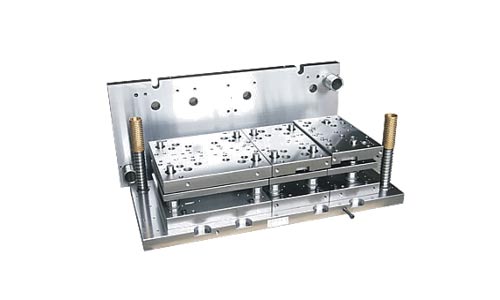

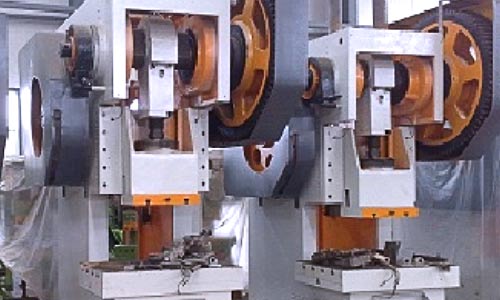

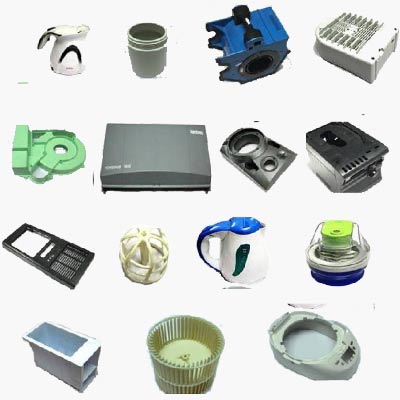

Established in 2002, invested by PowerFirst, locating in Dongguan city with 52,000㎡ land area, We mainly focus on laser-cutting, NC-punching, NC bending, die-casting, CNC machining, metal stamping, powder-coating, wet-painting, etc. We have more than 1000 employees and we have been aiming at improving the factory management, products quality and better customer service with creativity and enthusiasm to satisfy various customers’ requirement.