Factory Tour

Lobby

Office

Workshop

R&D

Meeting Room

Burn-in Test Room

PCBA Plant

PCBA Plant

PCBA Plant

Engineering Lab

Reliability Test Equipment

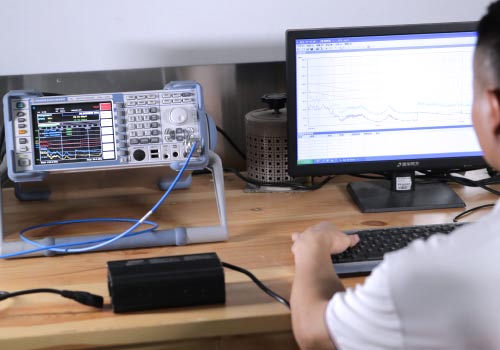

EMC Test

EMC Test

EMC Test

Cable Bending Test

Drop Test

Salt Spray Test

ATE

1

Hi-pot

Test

Temp & humi

Programmable Chamber

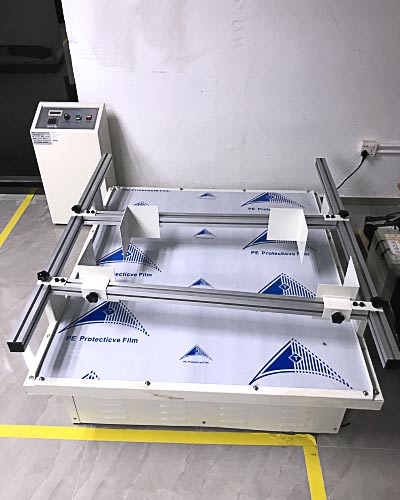

Transportation

vibration test

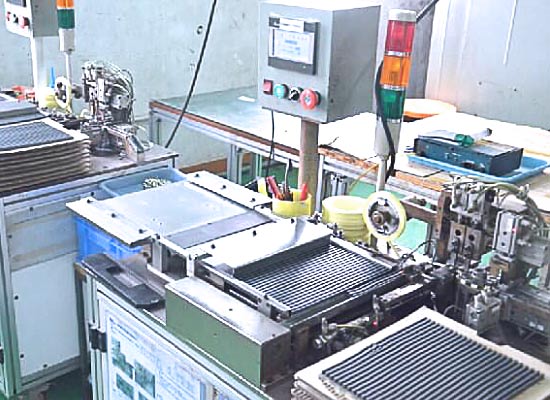

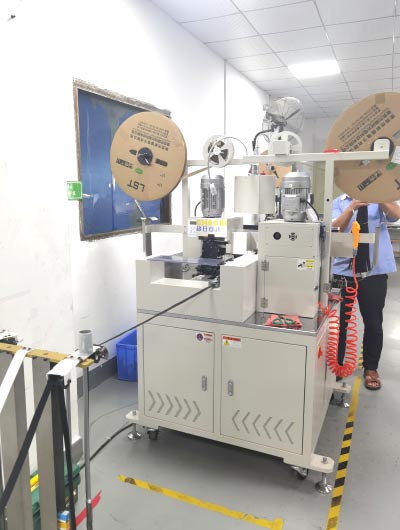

Auto Equipment

Automatic digital cutting machine

1

1

Digital machine for crimping, wire cutting, stripping, tinning and terminal block

Digital intelligent two-end twisting machine

1

1

Hydraulic terminal machin

1

1

Ultra-quiet semi-automatic terminal machine

1

Automatic glue dispensing

Automatic glue pouring

Automatic painting & baking

Automatic screw lock machine

Automatic welding machine

Maximize the Product Quality

We focus on quality control , every product is tested and

verified with strict standards.

We use rigorous and scientific experimental methods to

maximize the product Quality.

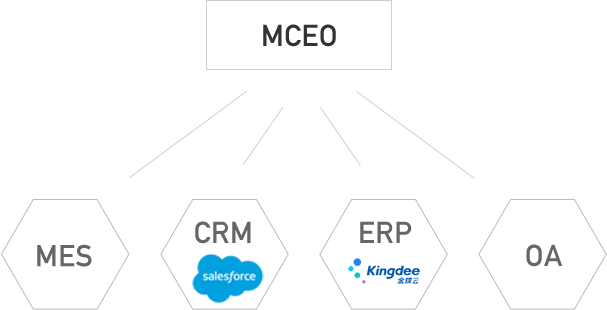

Information Construction

Production Flow Chart

Factory Tour

8 SMT Lines

Material Preparation Area

7 Assembly Lines

Warehouse

Advanced Equipment

Panasonic high speed

SMT machine

JTE series ten temperature zones reflow machine

SAMSUNG high speed

SMT machine

DESEN automatic

printer

SPI solder paste

detector

AOI

detector

X-ray PCB inspection

machine

Lead-free PCB wave

soldering machine

Burn-in

Chamber

Factory Tour

Winding

Assembly Line

FQC Test-Appearance Check

Dipping

Auto Test Line

Warehouse

Advanced Equipment

Auto Winding Machine

Auto Assembly Machine

Tape Wrapping Machine

Auto Dipping Machine

Auto Hi-pot Test

Auto Tester

IR Tunnel Furnace

UV Drying Chamber

Sheet Metal NC Fabrication

| Facility | Manufacturer | Qty | Capability |

| Laser Cutting | Trumpf(Germany) | 1 set | Max. Sheet Size 1500×3000 (mm)

Max. Thickness 20mm [Steel] 10mm [Stainless Steel] 8mm [Aluminium] |

| NC Punching | Finn-Power(Finland) | 5 sets | Max. Sheet Size 1270×2520 (mm)

Max. Thickness 3mm [Steel] 2mm [Stainless Steel] 4mm [Aluminium] |

| NC-Bending | Finn-Power(Finland)

Accurpress(Canada) |

4 sets

10 sets |

Max. Sheet Length 3000 (mm)

Max. Thickness 5mm [Steel] 6mm [Stainless Steel] 10mm [Aluminium] |

Die-casting

| Main Facility | Manufacturer | Qty | Capability |

| Die Casting (Aluminium) | UBE (Japan) | 1 set

2 sets 1 set 4 sets 2 sets |

850 ton

650 ton 530 ton 350 ton 250 ton |

| Die Casting

(Zinc) |

EG (China) | 2 sets

1 set |

130 ton

88 ton |

| Sand Blasting

Shot Blasting |

(China) | 2 sets

1 set |

–

– |

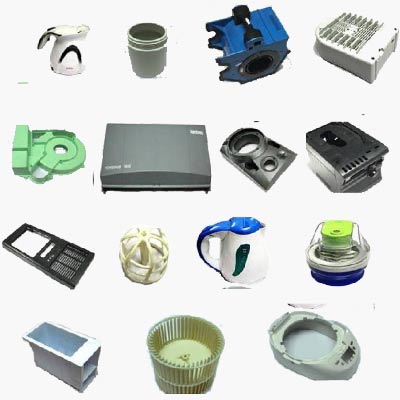

Tooling Making

| Main Facility | Manufacturer | Qty |

| Electro-Discharge | Charmilles (Swiss) | 10 sets |

| Wire-Cutting | Fanuc (Japan) | 12 sets |

| Surface Grinding | / | 6 sets |

| Milling | / | 4 sets |

| Tooling Type | Max. Monthly Output |

| Die Casting | 20 sets |

| Metal Stamping | 30 sets |

| Plastic Injection | 15 sets |

CNC Machining & Turning

| Facility | Manufacturer | Qty | Capability |

| CNC Machining | LGMazak (Japan)

Fanuc (Japan) |

183 sets | Max.Workpiece Size 400×900 (mm) |

| CNC Turning | Miyano (Japan)

Tsugami (Japan) |

150 sets | Max.Bar Diameter 1-5/8”

Max.Length 6.89” |

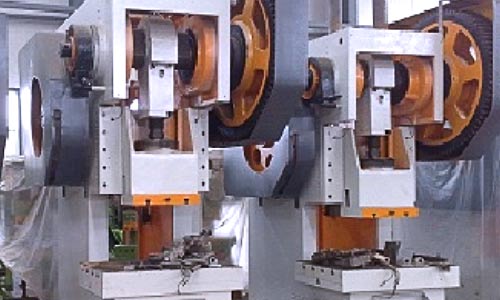

Metal Stamping

60sets Press Machines 45~200ton

Plastic Injection

| Equipment | Manufacturer | Tonnage/T | Quantity | Shot Glue/g

|

Mold Size(MM)

|

| Horizontal injection molding machine | HAITIAN (China) | 58 | 2 | 185 | 290*290 |

| 80 | 4 | 270 | 300*300 | ||

| 86 | 7 | 270 | 310*310 | ||

| 90 | 5 | 300 | 350*350 | ||

| 110 | 1 | 370 | 400*400 | ||

| 120 | 6 | 410 | 410*410 | ||

| 150 | 9 | 500 | 440*440 | ||

| 160 | 4 | 540 | 450*450 | ||

| 200 | 14 | 700 | 510*510 | ||

| 300 | 5 | 1600 | 660*660 | ||

| 320 | 3 | 1700 | 680*680 | ||

| 360 | 2 | 2150 | 720*720 | ||

| 380 | 4 | 2250 | 730*730 | ||

| 470 | 2 | 3200 | 780*780 |

Quality Assurance Equipment

| Main Equipment | Manufacturer | Qty |

| Die Casting | Mitutoyo (Japan), LK (UK) | 2 sets |

| 2D Measuring Machine

Projector Height Gage |

OGP (USA)

Mitutoyo (Japan), Rational (China) Tesa (Swiss), Nikon (Japan) |

1 set

2 sets 2 sets |

| X-ray Imaging Detector

Spectrometer Roughness Tester Hardness Tester |

Aolong (China)

Baird (USA) Mahr (Germany), Mitutoyo (Japan) (China) |

1 set

1 set 2 sets 2 sets |

Factory Tour

In 2000, we introduced advanced prepress digital technology, including computer-to-plate systems, color management system, soft proof, and more. Through the effective implementation of these technologies in the production process, we can effectively reduce costs, standardize management processes, control and improve the printing quality and the accuracy and effectiveness of communication.

Perfect post-press processing and binding equipment, can provide customers with a variety of processing services after the printing, including bronzing, paste, hit convex, flash powder, and so on.In addition, in the control of ink color and the deployment of spot color ink, the X-Rite computer Ink Formulating System is used to measure the spectrum of various colors and compared with the standard color through the spectro densitometer, then select the best solution of the least color difference, the lowest cost and the best printability. The spot color ink with the most accurate color was prepared in the shortest time. In addition, we also master a variety of ink color changing technology, special glazing three-dimensional texture, two-dimensional / three-dimensional optical variable design (OVD) stamping technology, and combine various high-tech anti-counterfeiting technologies on printed products.

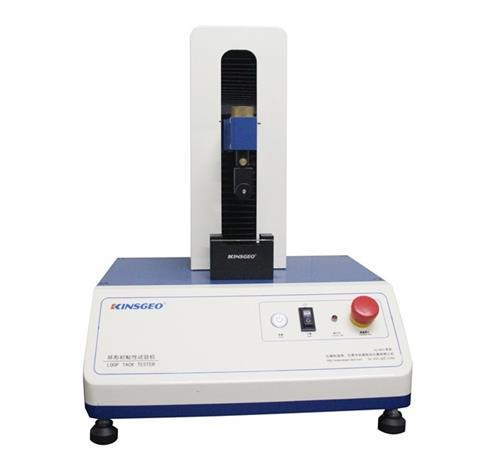

Testing laboratory

Early sticky tester

Constantly sticky tester

Friction tester

Pantone chromatograph

| Detection type | Equipment name | Guideline | Used in |

| Sticky test | Electronic stripping test machine | GB2792-1998 | Raw Material Test |

| Early sticky tester | GB4851-1998 | Raw Material Test | |

| Constantly sticky tester | GB4852-2002 | Raw Material Test | |

| Operating environment simulation test | Constant temperature and humidity test box | ——— | Raw Material Test |

| Light aging test box | HG/T3689-2001 | Raw Material or Finished Product Test | |

| Friction tester | GB7706-1987 | Finished Product Test | |

| Color detection | Spectrophotometer | ——— | Finished Product Test |

| Bar code tester | GB12904-2003 | Finished Product Test | |

| Pantone Chromatograph | ——— | Design Product /Finished Product Test | |

| Electrostatic detector | ——— | Finished Product Test |

Printing Equipment

Heidelberg Subaru SM52

HONTEC RS260-8C satellite-wide rotary presses

LINGTIE screen printing machine

DASHEN DS-260R rotary press

JOYSUN screen printing machine

auto screen printing machine

Automatic rotary press

Semi automatic screen printing machine

Trademark machine

| Facility | Brand & Model No. |

Quantity |

| Six-color printing presses | Heidelberg Subaru SM74-6L |

1 |

| Four-color printing presses | Heidelberg Subaru SM52 |

1 |

| Four-color printing presses | Heidelberg India Pa PM52 |

1 |

| Five-color printing presses | Heidelberg Indian Pa PM74 |

1 |

| Two-color printing presses | Heidelberg SORD |

1 |

| Two-color printing presses | Heidelberg MO |

1 |

| Monochrome presses | Heidelberg GTO |

1 |

| Rotary press | DASHEN DS-260R |

2 |

| Intermittent rotary presses | Iwasaki (LRW) LR25 |

1 |

| Satellite-wide rotary presses | HONTEC RS260-8C |

2 |

| Printing presses | ORTHOTEC CSL3022 |

1 |

| Half-rotary presses | Iwasaki (IWASAKI) 280 |

1 |

| Printing presses | DASHEN 210 |

1 |

| Digital printing presses | HP Indigo 6900 |

2 |

| Continuous screen printing machine | LABELMEN PWS-310 |

1 |

| Continuous screen printing machine | JOYSUN |

1 |

| Automatic screen printing machine | LINGTIE |

2 |

Processing Equipment

Punching machine

Convex processing

Die cutting machine

Die cutting machine

| Facility | Brand & Model No. | Quantity |

| Cutting Machine | XIN WANG/ BO XING | 2 |

| Slitting Machine | WEI SHI DA | 2 |

| Punching Machine | BLPA-25, NCP-45, Kingto | 5 |

| Oil-based laminating machine | FYB1000 | 2 |

| Water-based laminating machine | LING YI | 5 |

| Die Cutting Machine | WEI SHI DA, KUN LUN, LING YI | 8 |

| Round Knife Machine | HA DE | 1 |

| Hole Making Machine | CCD-107 | 1 |

| Laser Cutting Machine | YA CHAO, HE LI | 3 |

| Rubber Slitter | ZHENDE | 1 |